WPD woltman water meter

- Size Range: DN40~DN500

- Pulse output: Reed switch

- Protection: IP68

- Accuracy: R160, R200, R250

- Temperature: T50, T90, T130

Application

♦ Recording the total amount of cold water flowing through the water pipe, it is a removable element woltman water meter for industrial and irrigation application

Features

♦ The full set YT-Flow woltman series of water meters is imported from German technology with removable structure. The water meter does not have to be removed from the pipeline, so the movement can be pulled out repair or replacement.

♦ The counter is sealed with copper skin with the advantages of the clear reading kept for a long time, good universality of the measuring mechanism, reduction of spare parts, magnetic connection, small transmission resistance, sensitive and reliable operation, low pressure loss and long service life.

♦ All the materials in contact with water, consciously selected by the known resistance to corrosion; Iron body with inside and outside epoxy coating for protecting the corrosion; The ROTATING indicator register for the most comfortable reading position; The copper can super dry register with IP68 protection; The interchangeable, removable measuring mechanism can be easy removed from the body for checking, maintaining and replacing, no needs to dismantle the body form the pipe; Suitable for any position installation; Low pressure loss; No effected by external magnetic fields; Pulse output always ready, and Pulse output AS OPTION; The Pulse Output Device consists of a plastic housing with a Reed Switch, and 1,5 m cable with 2 cores in Red and Black; Electric Data: Vmax=24AC/DC; Imax=0,01A;

♦ High accuracy,achieve R200 to R400;

Remarks

♦ The technical parameters of the water meter are in accordance with the national standard GB/T 778.1~3-2007 (ISO4064-1~3:2005, IDT).

♦ The YT-Flow woltman DN40~600 hot water meter is available. The highest temperature can reach 130℃ and the counter can rotate at 360°.

♦ It is TURBINE Woltaman water meter with magnetic transmission, super dry type register for Industrial and Irrigation application has the sizes from Dn40 to Dn600 designed by YT-Flow and meets to the requirements of Directive 2004/22/EC on measuring instruments and of European Standard EN14154.

Capacity of the Pulse Emitter:

Size |

m3/pulse |

|

Dn40 to Dn125 |

0.1 |

1 |

Dn150 to Dn200 |

1 |

10 |

Dn250 to Dn600 |

10 |

100 |

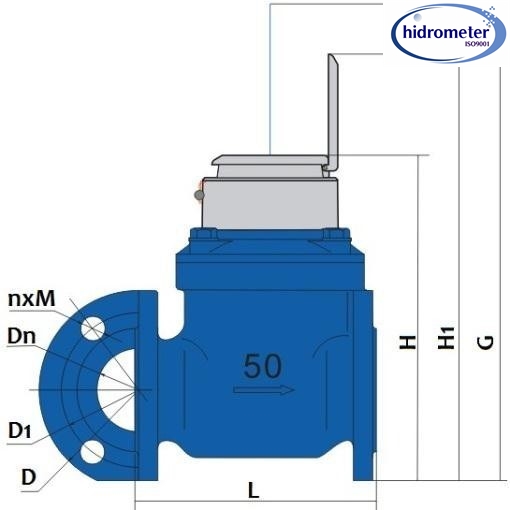

DIMENSION:

E.g.The Flange Standard under ISO 7005-2:1998(E) PN16 as:

Dn(mm) |

50 |

80 |

100 |

150 |

200 |

250 |

300 |

400 |

500 |

L (mm) |

200 |

225 |

250 |

300 |

350 |

450 |

500 |

600 |

800 |

H (mm) |

210 |

265 |

270 |

310 |

370 |

490 |

576 |

630 |

740 |

H1 (mm) |

320 |

350 |

370 |

520 |

620 |

710 |

750 |

830 |

930 |

D (mm) |

165 |

200 |

220 |

285 |

340 |

405 |

460 |

580 |

715 |

D1 (mm) |

125 |

160 |

180 |

240 |

295 |

355 |

410 |

525 |

650 |

G.W.(Kg) |

9.5 |

11.6 |

14.5 |

27.5 |

48 |

94 |

114 |

199 |

340 |

Flow rate technical specification

Size |

mm |

50 |

80 |

100 |

150 |

|

200 |

250 |

300 |

|

400 |

500 |

|

R |

Q3/Q1 |

250 |

250 |

250 |

250 |

200 |

200 |

160 |

|

160 |

160 |

||

Q4 |

m3/h |

78.8 |

125 |

200 |

500 |

787.5 |

1250 |

2000 |

3125 |

5000 |

|||

Q3 |

m3/h |

63 |

100 |

160 |

400 |

630 |

1000 |

1600 |

2500 |

4000 |

|||

Q2 |

m3/h |

0.4 |

0.63 |

1 |

2.56 |

|

5 |

8 |

16 |

|

25 |

40 |

|

Q1 |

m3/h |

0.25 |

0.4 |

0.63 |

1.60 |

|

3.2 |

5 |

10 |

|

15.6 |

25 |

|

Max. Reading |

m3 |

|

999999,999 |

|

9999999,99 |

|

99999999,9 |

|

|||||

Min. Reading |

m3 |

|

0,0005 |

|

|

0,005 |

|

|

|

0,05 |

|

||

Max. Temperate |

℃ |

|

|

|

|

|

T30 or T50 |

|

|

|

|

|

|

Max. Temperate |

℃ |

|

|

|

|

|

T30 or T50 |

|

|

|

|

|

|

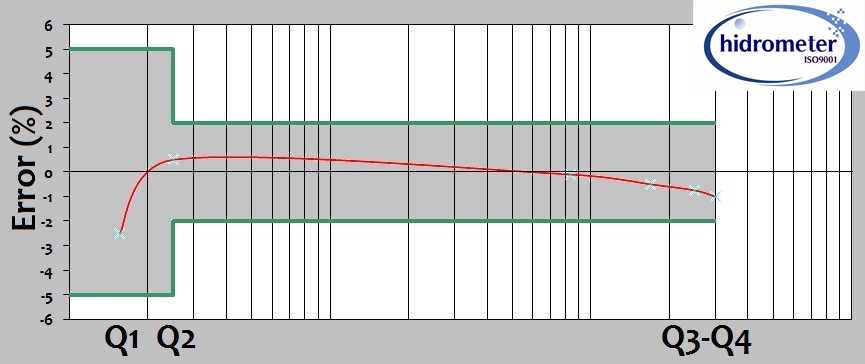

Accuracy Chart

MAX. PERMISSION ERROR:

From Q1 inclusive up to but excluding Q2 is ± 5%;

From Q2 inclusive up to and including Q4 is ± 2% for T30 and ± 3% for T50 ;

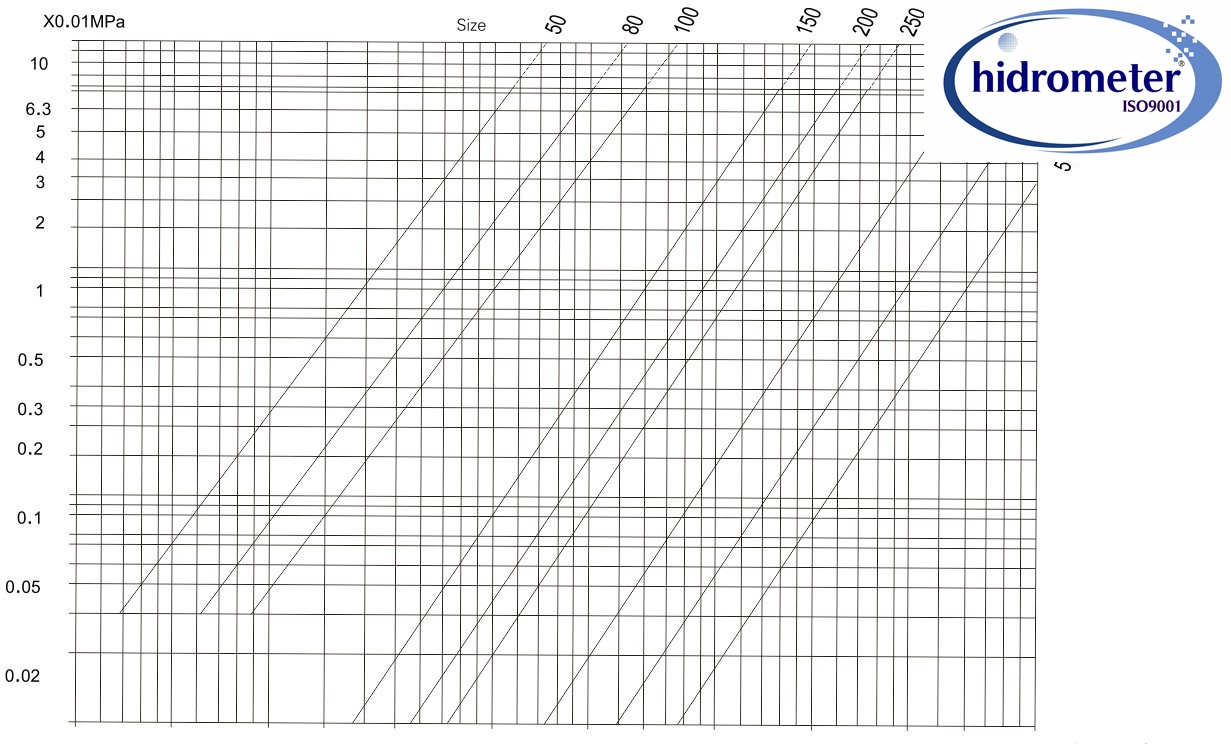

Pressure loss

Installation:

*The meter can be installed in any position with the direction of the flow as indicated by the arrow cast in the meter body, with the register face upwards.

*The meter shall have 5 diameter straight pipes ahead of the meter and 3 diameter straight pipes after insure proper flow through the meter.

*Pipeline shall be flushed before installation.

*The meter should be constantly full of water during operation

Performance of Electrodes