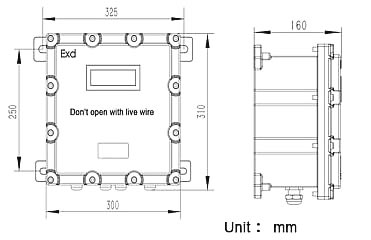

Explosion Proof Ultrasonic Flow Meter

- Accuracy:≤1%

- Velocity:0 ~ ±10 m/s, forward and reverse measurement

- Pipe Size:DN32 - DN6000 mm

- Medium Temperature:-30℃ ~160℃

- Power Supply:DC8~36V, AC10~30V

Principle

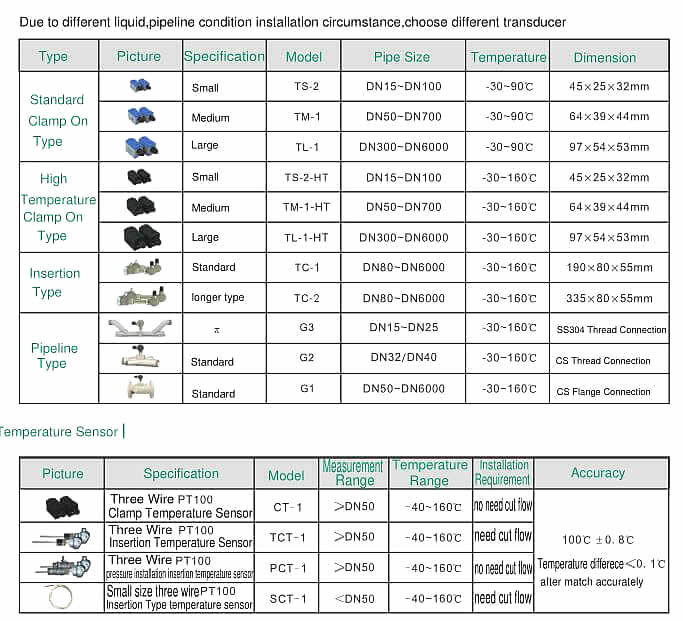

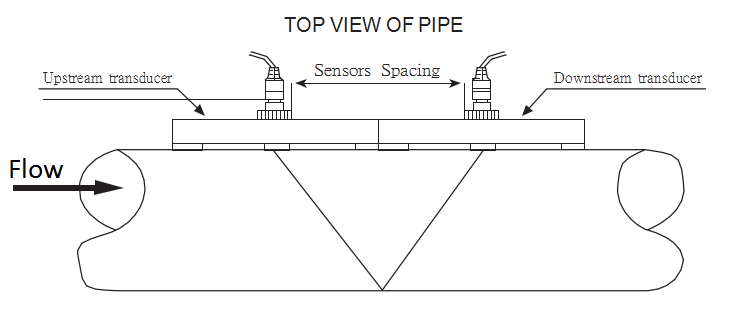

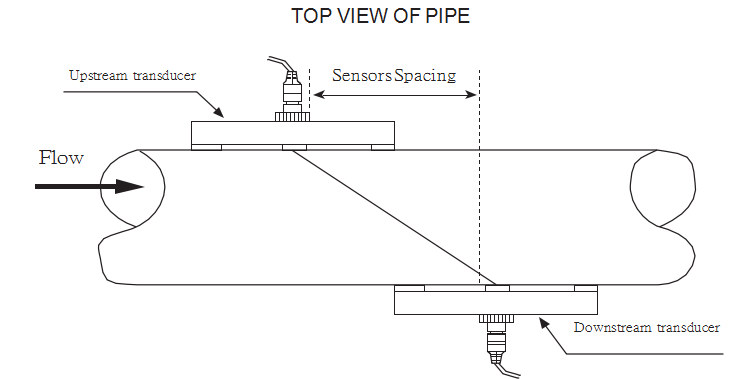

Ultrasonic water meter is designed to measure the fluid velocity of liquid within a closed conduit. The transducers are a non-contacting, clamp-on type, which will provide benefits of non- fouling operation and easy installation.

Transit time ultrasonic flow meter send and receive ultrasonic waves between transducers in both the upstream and downstream directions in the pipe. At no flow conditions, it takes the same time to travel upstream and downstream between the transducers. Under flowing conditions, the upstream wave will travel slower and take more time than the (faster) downstream wave. When the fluid moves faster, the difference between the upstream and downstream times increases. The transmitter processes upstream and downstream times to determine the flow rate.

Features

• 0.5% of linearity

• 0.2% of repeatability

• 4 flow totalizers

• Patent balanced lower-voltage multi-pulse ultrasonic igniting

• built-in date totalizers

• built-in data-logger

• Work properly near transverters

• 0.5 second totalizing period

• 100 Pico-second resolution of time measurement

.jpg)

.jpg)

Optional

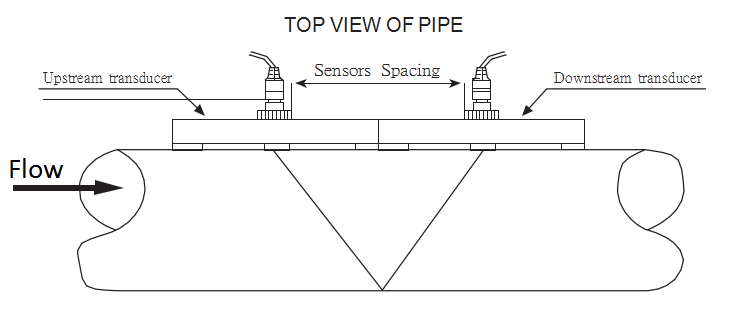

V-method Installation

V-method installation is the moswidely used mode for daily measurement with pipe inner diameters ranging from 15 millimeter to 200 millimeter. It is also called reflective mode or method.

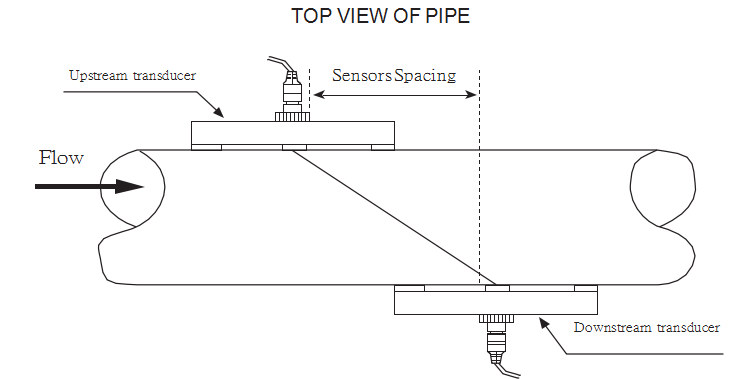

Z-method Installation

Z-method is commonly used when the pipe diameter is between 300 millimeters and 500 millimeters.

W-method Installation

W-method is usually used on plastic pipes with a diameter from 15 millimeters to 100 millimeters

.png)

Sel Battery-powered Magnetic Flow Meter

Battery-powered Magnetic Flow Meter Selection Table

Performance of Electrodes

.jpg)

.jpg)

.jpg)

.png)